ACC CLEAR™ Anti-Fog coatings offer superior anti-fog performance at a lower price than common in-resin or masterbatch alternatives. Topical in-line application via extrusion or thermoforming provides instant, long-lasting anti-fog treatment without jeopardizing the intrinsic properties of the substrate. Once coated, the sheet/substrate can be thermoformed or left in roll stock without worrying about premature activation due to heat and/or aging.

ANTI-FOG COATINGS

Topical Anti-Fog Solutions

ACC CLEAR™ Anti-Fog Coatings

Our Anti-Fog Coating Applications

Our ACC CLEAR Anti-Fog coatings can be applied to both rigid and flexible films. We customize these coatings so you apply them using your existing coating equipment, including roll, dip/squeegee, spray, Flexo and Rotogravure coating equipment.

Anti-fog coatings are commonly used in a wide variety of food packaging applications, including:

- Roaster domes: 8+ hours of performance in hot display case

- Sushi packaging or other hot filled product refrigerated immediately

- Appetizer, fruit and vegetable platters

- Fresh-cut produce QSR/takeout containers: Moisture control properties like anti-fog have been proven to extend product life

- Salad bags: 3+ weeks of performance

- Bakery containers, cake and pie lids

- Ask about our PPE applications

- … and more

Benefits of ACC CLEAR Anti-Fog Coatings

Versatile. ACC CLEAR Anti-Fog coatings provide instant, long-lasting anti-fog protection for a variety of hot and cold fill/storage applications, such as thermoformable containers, lidding film and and various other foodservice applications.

Our coatings can be designed for any substrate and application — even the most obscure or non-standard — in addition to those listed above. Coatings can be designed with built-in slip, demold and denesting technologies, eliminating the need for silicone or internal anti-block.

Our clear coatings deliver proven anti-fog properties for:

- Rigid substrates such as APET, RPET, PP, OPS, HIPS, PLA and many others

- Flexible films such as OPP, PE, CO-Ex films, PLA, PET and other multi-layer structures

Heat Sealable. ACC CLEAR Anti-Fog coatings can be made heat sealable, eliminating the need to “pattern print” and register the anti-fog in flexible applications, and allowing formed parts to be used in conjunction with lidding films and labeling stock.

FDA Compliant. ACC CLEAR Anti-Fog coatings are FDA-compliant for direct food contact applications in accordance with food additive regulations.

Preferred Over In-Resin/Masterbatch Anti-Fogs

Compared with ACC CLEAR Anti-Fog coatings, in-resin/masterbatch anti-fog coatings are clearly inferior:

- More expensive because more material is required to achieve the same result

- Clarity is impacted

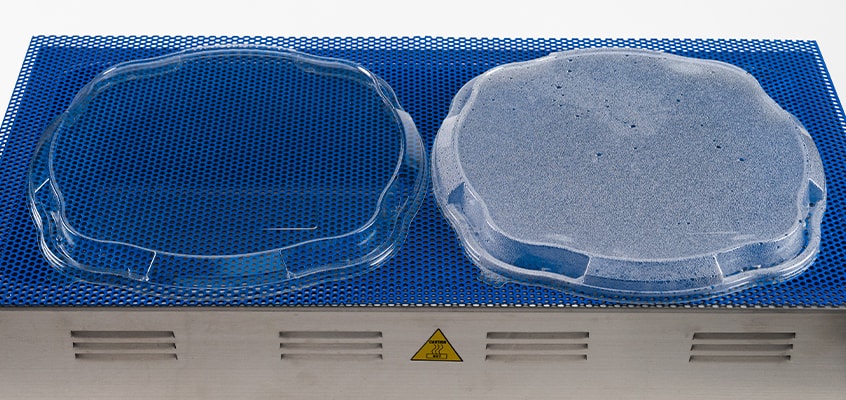

- Anti-fog blooms prematurely and causes a white powdery substance when stored

- Takes time and heat for anti-fog to activate: not suitable for cold/ambient applications

ACC CLEAR Anti-Fog Coatings Downloads

Seal-Thru™ Anti-Fog Coatings for Flexible Packaging

Anti-Fog Coatings for Rigid Thermoformable Packaging

Anti-Fog Coatings for Injection Molding